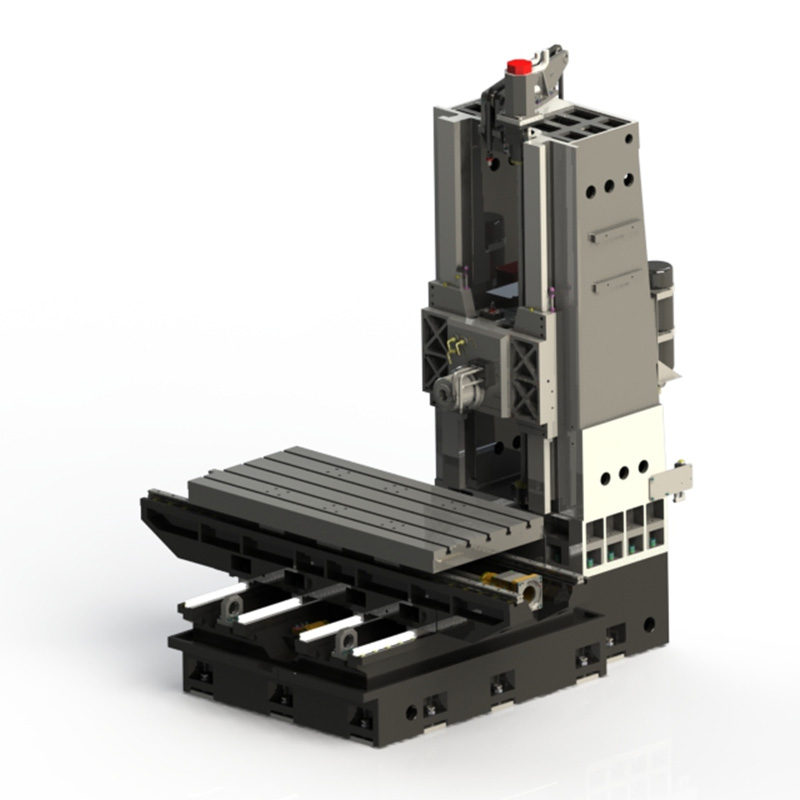

High-Efficiency and Precision Multi-Surface Machining

Equipped with a fourth axis, the workpiece can be machined on multiple surfaces in a single setup. Continuous milling, drilling, boring, and tapping operations reduce cycle time, minimize clamping errors, unify reference points, and ensure high accuracy of hole systems and end faces with excellent parallelism, perpendicularity, and consistency.

Superior Chip Removal Performance

With a horizontal spindle design, chips naturally fall into the chip chute by gravity, minimizing their impact on machining accuracy and tool life. This design is ideal for efficient and stable processing of steel and cast iron materials.

Optimized for Box-Type Components

Perfectly suited for machining gearbox housings, engine blocks, and other box-type components, the machine excels at handling complex hole systems and contours—making it an essential solution for the automotive and construction machinery industries.

Strong Automation Integration

Designed for seamless integration with robots and automated storage systems to form an FMC, it enables automatic loading, unloading, and part transfer. This high level of automation supports large-scale unmanned production while significantly reducing labor costs.

| Project | Unit | 1165 | 1290 | 1814 |

|---|---|---|---|---|

| X-axis travel | MM | 1100 | 1200 | 1800 |

| Y-axis travel | MM | 650 | 900 | 1400 |

| Z-axis travel | MM | 750 | 700 | 900 |

| Workbench area | MM | 650*1200 | 700*1360 | 900*2000 |

| Workbench maximum load | kg | 800 | 1000 | 1600 |

| Distance from spindle center to workbench surface | MM | 310-1060 | 60-960 | 20-1420 |

| Distance from spindle face to the center of the workbench | MM | 175-825 | 150-850 | 200-1100 |

| Spindle speed | rpm | STD:8000 belt | STD:6000 belt | STD:6000 belt |

| The spindle chain degree | / | BT40 | BT50 | BT50 |

| Spindle motor power | KW | 11.0-15.0 | 11.0-15.0 | 15.0-18.5 |

| Spindle cutting torque | N.m | 105 | 105 | 143 |

| X.Y.Z axis motor power | KW | 3*3*3 | 3*3*3 | 3*3*3 |

| Triaxial rapid displacement | MM | 24*14*24 | 12*12*12 | 12*12*12 |

| Cutting feed speed | MM | 1-10000 | 1-10000 | 1-10000 |

| Positioning accuracy | MM | 300/±0.005 | 300/±0.005 | 300/±0.005 |

| Repetitive positioning accuracy | MM | 300/±0.003 | 300/±0.003 | 300/±0.003 |

| Number of tools | set | 24 | 24 | 24 |

| The system configuration | / | Mitsubishi/FANUC/SYNTEC/Siemens | ||

| Mechanical dimensions | MM | 4945*4355*3666 | ||

| Machine weight about | kg | 6000 | 8000 | 12000 |