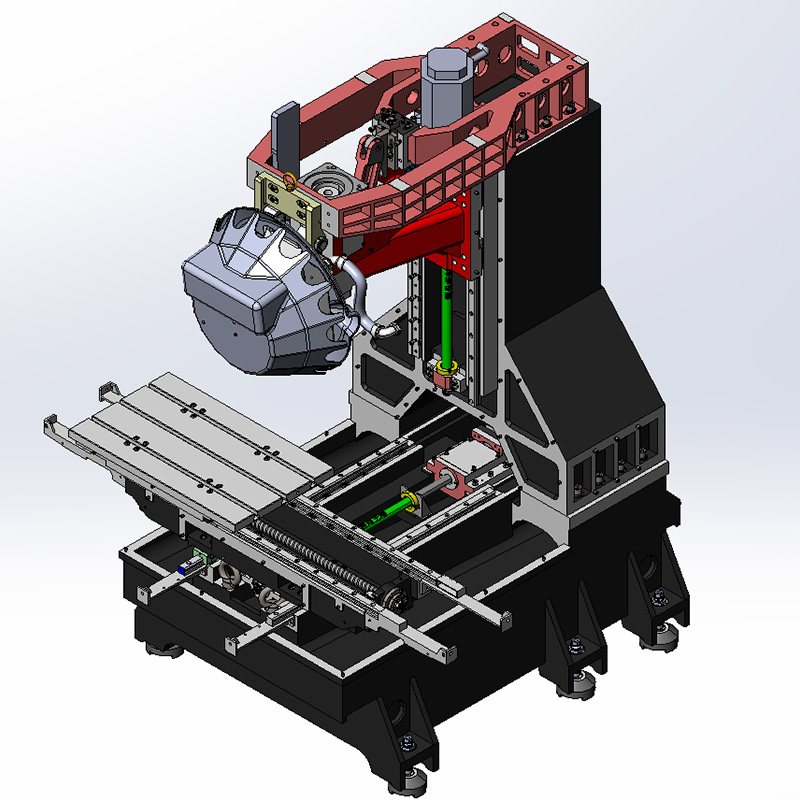

Outstanding Machining Performance

Equipped with a high-speed spindle ranging from 15,000 to 24,000 rpm, rapid traverse rates of 48–60 m/min, and tool change times of just 0.8–1.5 seconds, the tapping center achieves exceptional drilling and tapping efficiency beyond that of conventional machines. It is ideal for machining aluminum, copper, and plastic materials, widely used in 3C industries for components such as mobile phone frames and small precision hardware parts.

Compact Structure and Automation-Ready Design

The machine’s compact footprint—occupying only 1/2 to 2/3 of the space of a traditional vertical machining center—allows for dense workshop layouts. It can be easily integrated with automatic feeding systems or robotic loading/unloading units, supporting fully unmanned 24-hour mass production lines.

Low Energy Consumption and High Reliability

With a spindle power range of 5.5–11 kW, the tapping center combines low energy consumption with a robust and reliable structure. Its low failure rate and economical maintenance and tooling costs ensure excellent cost control and long-term production stability.

| Project | Unit | T6 | T7 |

|---|---|---|---|

| X-axis travel | MM | 600 | 700 |

| Y-axis travel | MM | 400 | 400 |

| Z-axis travel | MM | 350 | 350 |

| Workbench area | MM | 700×420 | 780×420 |

| Distance from spindle nose to worktable | MM | 150-500 | 150-500 |

| Distance from spindle center to column guide surface | MM | 439 | 439 |

| Spindle speed | rpm | STD 20000 direct | |

| Spindle taper | / | BT30 | |

| Spindle motor power | KW | 7.5 | |

| Spindle cutting torque | N.m | 35.8-95.5 | |

| X, Y, Z axis motor power | KW | 1.8/1.8/3.0 | |

| Triaxial rapid traverse rate | M/min | 48/48/48 | |

| Cutting feed speed | MM/min | 1-10000 | 1-10000 |

| Positioning accuracy | MM | ±0.005/300 | ±0.005/300 |

| Repetitive positioning accuracy | MM | ±0.003/300 | ±0.003/300 |

| Number of tools | set | 21 | 21 |

| System configuration | / | Mitsubishi/FANUC/SYNTEC/Siemens | |

| Mechanical dimensions | MM | 1800×2547×2924 | 2000×2574×2925 |

| Machine weight (approx.) | kg | 3000 | 3200 |