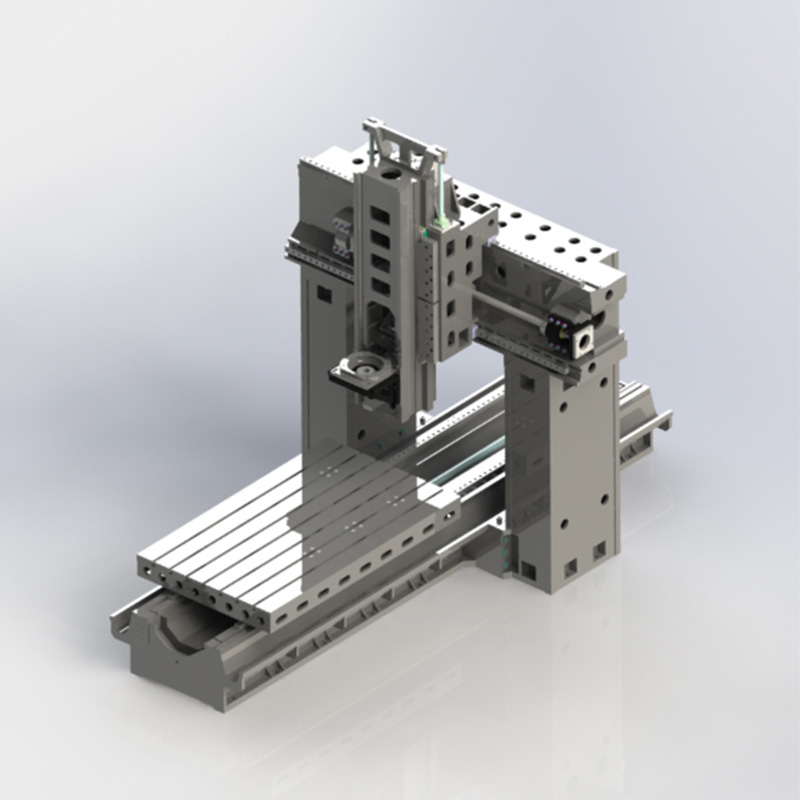

Oversized Capacity and Versatile Adaptability

The double-column crossbeam gantry structure offers an ultra-wide worktable and an X-axis travel exceeding ten meters, enabling the machining of large components such as machine tool beds, molds, and structural parts. The fixed table ensures excellent stability and easy calibration, supporting customized attachments to suit diverse machining requirements.

Exceptional Load-Bearing Performance

Built with a high-rigidity gantry frame, the machine provides a load capacity far beyond that of conventional vertical machining centers. The heavy-duty table can support components weighing hundreds of tons while maintaining structural stability and resistance to deformation during heavy cutting.

High Precision and Machining Stability

The strong beam-and-column structure ensures accurate spindle movement and outstanding rigidity. Equipped with precision linear guide drives, it achieves full-stroke accuracy for high-precision milling, boring, and drilling of large-scale workpieces.

Comprehensive Multi-Function Integration

The system supports various milling head configurations—vertical, horizontal, or universal—to realize five-face machining or five-axis linkage in a single setup. This multi-process integration reduces repositioning errors, shortens machining time, and significantly improves overall efficiency and accuracy.

| Project | Unit | 1012 | 1016 | 2015 | 2017 | 2019 | 3017 | 3019 | 4025 | 4027 |

|---|---|---|---|---|---|---|---|---|---|---|

| X-axis travel | MM | 1200 | 1600 | 2200 | 2200 | 2200 | 3200 | 3200 | 4200 | 4200 |

| Y-axis travel | MM | 1100 | 1100 | 1500 | 2100 | 2300 | 2100 | 2300 | 3000 | 3000 |

| Z-axis travel | MM | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Workbench area | MM | 900×1400 | 900×1800 | 1300×2200 | 1600×2200 | 1800×2200 | 1600×3200 | 1800×3200 | 2200×4000 | 2500×4000 |

| Workbench maximum load | T | 1.6 | 2 | 5.5 | 4 | 4 | 6 | 6 | 17 | 19 |

| Lanmen column spacing | mm | 1100 | 1100 | 1500 | 1800 | 2000 | 1800 | 2000 | 2500 | 2700 |

| Distance from spindle nose to worktable | MM | 140-940 | 140-940 | 150-950 | 70-1070 | 70-1070 | 70-1070 | 70-1070 | 250-1250 | 250-1250 |

| Spindle speed | rpm | STD:8000 belt | STD:8000 belt | STD:8000 belt | STD:6000 belt | STD:6000 belt | STD:6000 belt | STD:6000 belt | STD:6000 belt | STD:6000 belt |

| The spindle chain degree | / | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 |

| Spindle motor power | KW | 11.0-15.0 | 11.0-15.0 | 11.0-15.0 | 11.0-15.0 | 15-18.5 | 15-18.5 | 15-18.5 | 15-18.5 | 15-18.5 |

| Spindle cutting torque | N.m | 105 | 105 | 105 | 105 | 143 | 143 | 220 | 220 | 220 |

| X.Y.Z axis motor power | KW | 3*3*3 | 3*3*3 | 3*3*3 | 3*3*3 | 3*3*3 | 5.5*5.5*5.5 | 5.5*5.5*5.5 | 5.5*5.5*5.5 | 5.5*5.5*5.5 |

| Triaxial rapid displacement | MM | 12*12*12 | 12*12*12 | 12*12*12 | 10*10*10 | 10*10*10 | 10*10*10 | 10*10*10 | 8*10*12 | 8*10*12 |

| Cutting feed speed | MM | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-8000 | 1-8000 |

| Positioning accuracy | MM | 300/±0.005 | 300/±0.005 | 300/±0.005 | 300/±0.005 | 300/±0.005 | 300/±0.005 | 300/±0.005 | 300/±0.005 | 300/±0.005 |

| Repetitive positioning accuracy | MM | 300/±0.003 | 300/±0.003 | 300/±0.003 | 300/±0.003 | 300/±0.003 | 300/±0.003 | 300/±0.003 | 300/±0.003 | 300/±0.003 |

| Number of tools | set | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

| The system configuration | / | Mitsubishi/FANUC/SYNTEC/Siemens | ||||||||

| Mechanical dimensions | MM | 6528*4410*4200 | 6820*4900*4730 | 6710*5110*4125 | 8482*4800*4750 | 8835*5625*5000 | 10387*5556*5980 | 10900*6567*5250 | ||

| Machine weight about | T | 12 | 13 | 14 | 18 | 20 | 22.5 | 23 | 32 | 35 |