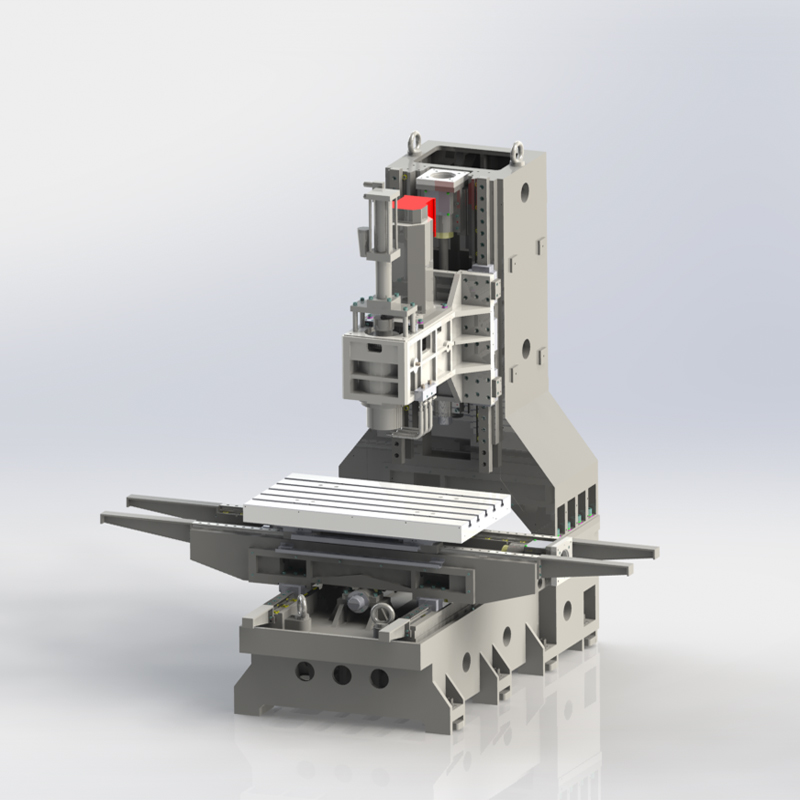

Powerful and Stable Cutting Performance

The Z-axis is designed with six flange-type sliders, ensuring exceptional rigidity and delivering powerful spindle cutting capability even under heavy-load conditions.

High-Speed, Vibration-Free Spindle Head Design

The headstock adopts a counterweight-free design to eliminate counterweight vibration and inertial lag. Combined with an enlarged servo motor, it enables rapid spindle response and smooth high-speed operation.

Optimized Structural Rigidity and Layout

Featuring a large-span herringbone column, widened base, and extended Y-axis guideway spacing, the machine provides superior stability. The optimized distance between the spindle box and table sliders, based on the Bessel principle, ensures powerful and steady cutting performance.

High Precision and Thermal Stability

The three-axis ball screws are pre-tensioned with a precision preloading process to effectively suppress thermal expansion, maintaining outstanding positioning accuracy and repeatability during continuous machining.

| Project | Unit | VMC645 | VMC855 | VMC966 | VMC1060 | VMC1165 | VMC1270 | VMC1370 | VMC1580 |

|---|---|---|---|---|---|---|---|---|---|

| X-axis travel | MM | 600 | 800 | 900 | 1000 | 1100 | 1200 | 1300 | 1500 |

| Y-axis travel | MM | 450 | 500 | 600 | 600 | 650 | 700 | 800 | 800 |

| Z-axis travel | MM | 450 | 500 | 600 | 600 | 600 | 700 | 700 | 700 |

| Workbench area | MM | 700×420 | 1000×500 | 1000×550 | 1100×500 | 1200×600 | 1400×700 | 1400×800 | 1700×800 |

| Workbench maximum load | kg | 250 | 500 | 600 | 600 | 800 | 1000 | 1200 | 1500 |

| Distance from spindle nose to worktable | MM | 135-585 | 120-670 | 120-720 | 120-750 | 130-730 | 120-820 | 120-820 | 135-835 |

| Distance from spindle center to column guide surface | MM | 488 | 550 | 640 | 655 | 710 | 770 | 860 | 870 |

| Spindle speed | rpm | STD 12000 direct / OPT 15000 direct | STD: 8000 belt / OPT: 10000 belt / OPT: 12000 direct / OPT: 15000 direct | ||||||

| Spindle taper | / | BT40 | BT40 | BT40 | BT40 | BT40 | BT40 | BT40 | BT50 |

| Spindle motor power | KW | 7.5 | 11 | 11 | 11 | 11 | 11 | 11 | 15 |

| Spindle cutting torque | N.m | 35.8-95.5 | 52.5-118 | 52.5-118 | 52.5-118 | 52.5-118 | 52.5-118 | 52.5-118 | 95.5-140 |

| X, Y, Z axis motor power | KW | 1.8/1.8/3.0 | 3.0/3.0/3.0 | 3.0/3.0/3.0 | 3.0/3.0/3.0 | 3.0/3.0/3.0 | 3.0/3.0/3.0 | 3.0/3.0/3.0 | 3.0/3.0/3.0 |

| Triaxial rapid traverse rate | M/min | 48/48/48 | 48/48/48 | 36/36/24 | 36/36/36 | 36/36/36 | 36/36/36 | 36/36/36 | 24/24/24 |

| Cutting feed speed | MM/min | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 |

| Positioning accuracy | MM | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 |

| Repetitive positioning accuracy | MM | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 |

| Number of tools | set | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

| System configuration | / | Mitsubishi/FANUC/SYNTEC/Siemens | |||||||

| Mechanical dimensions | MM | 2000×2400×2600 | 2650×2822×2925 | 2580×2700×2440 | 2800×3200×2950 | 2900×3200×2950 | 2950×2990×3090 | 3800×3365×3100 | 4250×3881×3145 |

| Machine weight (approx.) | kg | 4000 | 4500 | 4700 | 5300 | 5800 | 6500 | 7000 | 8500 |